Steel Reinforce Laminated with Rubber Bridge Bearing

Basic Info.

| Model NO. | HG112 |

| Material | Steel |

| Structure | Laminated Rubber |

| Activity | Multi Direction Movable Bearing |

| Usage | Beam Bridge, Highway Bridge, Railroad Bridge |

| Design Vertical Load | 1000-70000kn |

| Insert | Reinforced Steel |

| Transport Package | as Your Needed |

| Specification | AASHTO |

| Trademark | Haigger |

| Origin | China |

| HS Code | 7604299000 |

| Production Capacity | 500, 000PCS/Year |

Product Description

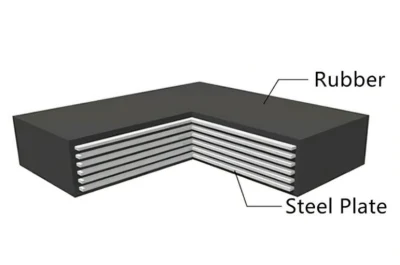

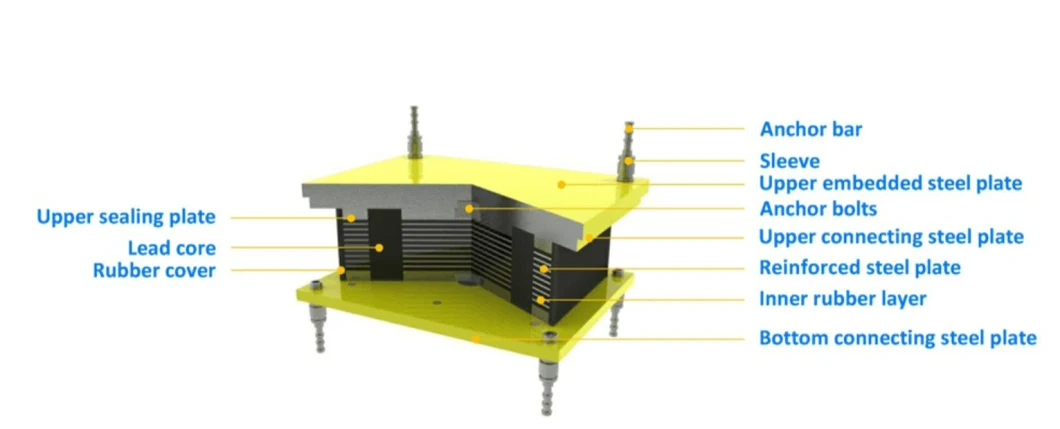

Product DescriptionElastomer Bearing Pad are made of multiple layers of rubber sandwiched with and bound to thin steel sheets,and then through vulcanization.Its vertical rigidity is sufficient to bear the perpendicular load and to shift the pressure reliably from the superstructure to the piers. Its elasticity is high enough to suit the rotation of the beam end.Its shear deformation is sufficient to cope with the horizontal displacement of the superstructure.

| Standard | JT/T4-2004 | BS5400 Section 9.2 | |||

| Rubber | Natural Rubber | Neoprene CR | Natural Rubber | Neoprene CR | |

| Hardness(IRHD) | 60±5 | 60±5 | 50±5/60±5/70±5 | ||

| Tensile Strength (M Pa)≥ | 18 | 17 | 17 | 15.5 | |

| Ultimate Elongation (%)≥ | 450 | 400 | 450/400/350 | 400/350/300 | |

| Compression Set | 70 o C×22h | 70 o C×22h | 100 o C×22h | ||

| <30 | <15 | <30 | <35 | ||

| Heat Resistance | Test Condition | 70 o C×168h | 100 o C×70h | 70 o C×168h | 100 o C×48h |

| Change in Hardness | -5,+10 | 0,+10 | <10 | <15 | |

| (IRHD) | |||||

| Rate of Tensile Strength Reduction(%) | <15 | <15 | |||

| Rate of Ultimate | <20 | <40 | <20 | <40 | |

| Elongation Reduction | |||||

| (%) | |||||

| Ozone Resistance | 25~50pphm,20% strain | 25~50pphm,20% strain | |||

| 40 o C×96h | 30 o C×96h | ||||

| No Cracks | No Cracks | ||||

Forens, founded in early 2000, is specialized in manufacturing bridge bearing, bridge expansion joint, building expansion joint, and construction bearing. Our company has a registered capital of 8, 800, 000 us dollars, it covers an area of 50, 000 square meters, with a construction area of 20, 000 square meters, there are 200 staff now in our company.Forens is a modern enterprise which has a leading technology in China, and the advanced production equipment, perfect testing equipment.It has passed the ISO9001: 2008 international quality system certification and ISO14001: 2004 environmental management system certification.

We have a strong technical force and a professional installation team, perfect after-sales service in our company. Over many years, our products have been widely used in highway, railway bridges, public buildings, etc. We have also successfully take participate in many national key projects and many landmark project. Such as: Pudong international airport, Beijing capital international airport and hangzhou international airport, chengdu international airport, xi'an international airport; Shanghai maglev, Shanghai light rail, light rail Beijing, nanjing metro; Shanghai hongqiao hub, and guiyang six broad river bridge, hunan zhuzhou xiangjiang river bridge, wuhan tianxingzhou yangtze river bridge, zhejiang zhujiajian bridge.

1.Safety package, Three steps of packages,pearl cotton,carton and plywood for the transportation2.100% test before delivering (ensure the quality)3.Item shipped in about 15-30 working days against payment depends on the quantity 4.Tracking number will be sent to you as soon as we ship the product

| FAQ(Frequently Asked Questions) |

| 1. You are a trading company or manufacturer? |

| -We are manufacturer, and have our own factory. |

| 2. What certificate do you get? |

| - ISO9001-2008. |

| 3. What is your MOQ? |

| -100m. |

| 4. What is your delivery time when making mass production? |

| -About 15 days, the actual time depends on your order quantity. |

| 5. Can you do OEM? |

| -Yes, we can. OEM is welcomed. |

| 6. What is your sample policy? |

| -We offer free samples, and the buyer takes responsibility of the express charge. |

| 7. How long will it take to prepare samples? |

| -About 3-4 working days. |